The Power of PP PS Sheet Extrusion Lines: Revolutionizing the Plastic Industry

Plastic is a versatile material used in countless applications, from packaging to consumer goods. Among the various methods of plastic processing, extrusion plays a vital role in shaping the future of the industry. The PP PS sheet extrusion line, specifically, has gained prominence in producing high-quality plastic sheets that serve as the foundation for a wide range of products.

In this article, we will explore the significance of PP PS sheet extrusion lines, their role in the manufacturing process, and why TZMachinery is a leading player in providing cutting-edge solutions in this space.

What is a PP PS Sheet Extrusion Line?

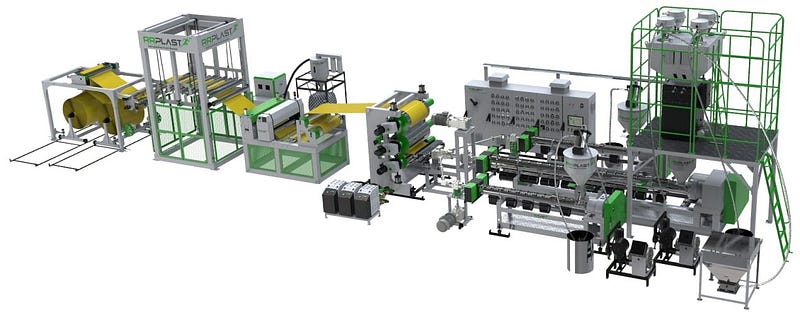

At its core, a PP PS sheet extrusion line is a specialized production line designed to extrude polypropylene (PP) and polystyrene (PS) sheets. The extrusion process involves melting plastic pellets and forcing them through a mold to form a continuous sheet of material. This sheet can then be used for various applications, including packaging, food containers, and more.

PP and PS are two of the most widely used thermoplastic polymers due to their versatility, cost-effectiveness, and ease of processing. PP offers excellent chemical resistance and is lightweight, while PS is known for its clarity and rigidity. Together, they provide an ideal combination for many industries looking for quality plastic sheets.

Why Choose a PP PS Sheet Extrusion Line?

The demand for high-quality plastic sheets continues to grow, and for good reason. The applications of PP and PS sheets are vast, ranging from the food industry to retail packaging and even medical devices. So, what makes the PP PS sheet extrusion line so critical in meeting these demands?

- High Production Efficiency

PP PS sheet extrusion lines offer exceptional production efficiency. By using advanced technologies and automated systems, these lines can produce large quantities of high-quality sheets with minimal downtime. The result is faster production times and lower operating costs, which is essential for businesses looking to scale. - Cost-Effective Solution

As a solution provider, TZMachinery specializes in providing high-value plastic extrusion lines. The PP PS sheet extrusion line offers an affordable way to manufacture quality plastic sheets. These lines help manufacturers achieve optimal performance while minimizing energy consumption, reducing waste, and lowering overall production costs. - Versatility in Applications

From packaging to industrial products, PP and PS sheets serve a broad array of applications. Manufacturers can create custom sheets in various sizes, thicknesses, and colors, making them ideal for packaging, food containers, electronics, automotive parts, and much more. The PP PS sheet extrusion line offers unparalleled flexibility in adapting to diverse customer needs. - Environmentally Friendly Production

In a world that is increasingly focused on sustainability, PP and PS sheets made from recyclable materials are becoming a priority for many industries. The PP PS sheet extrusion line is designed to be energy-efficient, and when used with recycled materials, it contributes to reducing environmental impact. TZMachinery’s commitment to providing sustainable manufacturing solutions helps businesses align with global eco-friendly goals.

How TZMachinery is Leading the Charge in PP PS Sheet Extrusion Technology

TZMachinery stands out as a professional solution provider and manufacturer of plastic sheet extrusion lines, including the PP PS sheet extrusion line. The company’s expertise and focus on innovation have enabled it to meet the highest industry standards while ensuring that its clients benefit from cutting-edge technologies.

Quality and Precision

One of the key advantages of choosing TZMachinery for PP PS sheet extrusion lines is the company’s commitment to quality. TZMachinery’s systems are engineered for precision, ensuring that each sheet produced meets strict quality standards. Whether you need a consistent thickness, superior surface finish, or high transparency, TZMachinery’s extrusion lines offer the reliability required to deliver superior results.

Customization and Flexibility

TZMachinery understands that each customer has unique requirements. That’s why their PP PS sheet extrusion lines are designed to be highly customizable. From adjusting the speed of production to changing the dimensions of the sheets, customers can tailor the machine to their specific needs. TZMachinery’s ability to provide flexible solutions ensures that businesses can meet the dynamic demands of the market.

Comprehensive After-Sales Support

The commitment to customer satisfaction doesn’t end with the installation of the PP PS sheet extrusion line. TZMachinery offers comprehensive after-sales support, including maintenance, troubleshooting, and training. With a dedicated customer service team, clients can ensure the longevity of their equipment and smooth production processes. This after-sales care ensures that companies get the maximum value from their investments.

Benefits of Using PP PS Sheet Extrusion Lines in Modern Manufacturing

The role of the PP PS sheet extrusion line goes far beyond just producing plastic sheets. It represents a cornerstone in the modern manufacturing process, offering a multitude of benefits to businesses and industries alike.

- Improved Product Quality

By ensuring that plastic sheets are uniform, smooth, and of consistent quality, extrusion lines enhance the overall product quality. Manufacturers can produce high-quality products, whether they are plastic packaging, trays, or containers, with fewer defects and higher precision. - Faster Time to Market

With automated extrusion lines, the production process is streamlined, which accelerates the time to market for new products. This gives businesses a competitive edge by reducing lead times and meeting customer demands quickly - Increased Cost Efficiency

TZMachinery’s PP PS sheet extrusion lines are designed to maximize operational efficiency, which helps companies reduce production costs. With advanced technology that minimizes material waste and optimizes energy use, manufacturers can produce more with less, ultimately boosting profitability. - Scalability for Growth

As businesses expand, their production needs evolve. The scalability of PP PS sheet extrusion lines allows manufacturers to increase output without sacrificing quality. Whether a business needs to ramp up production for a larger market or introduce a new product, TZMachinery’s extrusion lines grow with your business.

Conclusion: The Future of PP PS Sheet Extrusion Lines

As industries continue to innovate and adapt to consumer demands, the importance of reliable and efficient production methods becomes clear. PP PS sheet extrusion lines are a key part of this evolution, offering numerous benefits such as cost-efficiency, versatility, and sustainability. With TZMachinery at the forefront, businesses can trust that they are receiving the most advanced solutions available.

Looking ahead, the PP PS sheet extrusion line is poised to play an even greater role in sustainable manufacturing practices. By embracing these innovative solutions, businesses can not only meet current production demands but also future-proof their operations for a more sustainable and profitable future.

If you are in the market for cutting-edge extrusion technology, consider how TZMachinery’s PP PS sheet extrusion lines can help streamline your production processes and deliver high-quality results that align with global sustainability efforts. The future of plastic sheet manufacturing is here, and it’s more efficient, versatile, and eco-friendly than ever before.