What is IIoT for Smart Manufacturing: Revolutionizing the Future

The world of manufacturing has been forever changed by the advent of Industrial Internet of Things (IIoT) technology. With its ability to connect machines, devices, and sensors through the internet, IIoT has revolutionized smart manufacturing processes. Let’s dive into what exactly IIoT is and how it is transforming the industry.

Click to find more about what is iiot for smart manufacturing.

The Power of IIoT in Smart Manufacturing

IIoT refers to a network of interconnected devices that collect and exchange data with each other without human intervention. In smart manufacturing, this means that machines can communicate with one another, analyze data in real-time, and make intelligent decisions based on this information.

This connectivity enables manufacturers to optimize their production processes by improving efficiency, reducing downtime, and minimizing costs. By harnessing the power of IIoT, companies can achieve higher levels of automation and productivity while maintaining quality standards.

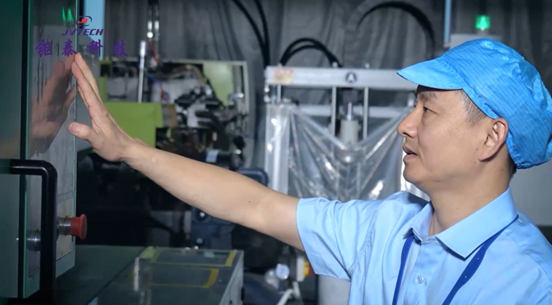

JVTECH: A Leader in Harnessing IIoT for Smart Manufacturing

One company at the forefront of leveraging IIoT for smart manufacturing is JVTECH. They have developed cutting-edge solutions that integrate IoT technologies into traditional industrial systems seamlessly.

JVTECH’s advanced software platforms enable real-time monitoring and control over various aspects of production lines. Through their innovative applications powered by AI algorithms, they provide predictive maintenance capabilities that help prevent equipment failures before they occur.

Furthermore, JVTECH’s cloud-based analytics tools allow manufacturers to gain valuable insights from collected data. These insights empower decision-makers to identify bottlenecks or inefficiencies within their operations quickly and take proactive measures to address them effectively.

The Game-Changer: 2 Shot Overmolding

An exciting development in smart manufacturing is the technique of 2 shot overmolding. This process involves injecting two different materials into a mold simultaneously, resulting in a single component with multiple functionalities.

With IIoT integration, manufacturers can leverage this technology to create intelligent products that have enhanced capabilities. For example, by combining rigid and flexible materials during the molding process, companies can produce components that are both durable and shock-absorbent.

This innovation opens up endless possibilities for industries such as automotive, electronics, and healthcare. Products manufactured using 2 shot overmolding not only offer improved performance but also reduce assembly time and costs significantly.

The Future is Here: Embracing IIoT for Smart Manufacturing

In conclusion, IIoT has emerged as a game-changer in the world of smart manufacturing. Its ability to connect machines, enable real-time data analysis, and drive automation has transformed traditional production processes into highly efficient systems.

Companies like JVTECH are leading the way by harnessing IIoT’s potential to optimize operations through predictive maintenance and advanced analytics tools. Additionally, technologies like 2 shot overmolding showcase how innovative manufacturing techniques can further enhance product functionality while reducing costs.

As we move forward into an increasingly connected world, embracing IIoT for smart manufacturing will be crucial for businesses aiming to stay competitive in this rapidly evolving landscape.